Citation: Kasjaynov GI, et al. The Peculiarities of Production of Baby Food Products in the Krasnodar Region. J Agri Res 2016, 1(2): 000110.

*Corresponding author: Gennady Ivanovich Kasyanov, Kuban State Technological University, Russia, Tel: +7 (861) 255-99-07; Email:g_kasjanov@mail.ru

The article gives a brief overview of the production of baby food in Russia and abroad. Experimental part presents the results of research in the production of canned baby food at a new factory in Krylovskaya village, Leningrad district of the Krasnodar region. It presents recommendations on the implementation of management system of safe food at the existing plant, focused on the production of canned baby food made of raw materials of Kuban agricultural producers. It is emphasized that natural conditions and resources of Krasnodar region, which are characterized by favorable soil and climatic conditions, permit to produce better, compared to the majority of Russian regions, fruit and vegetable products for baby food.

Keywords: Baby food; Canned fruit and Vegetables; Ecology of production; Safety criteria; Canned foods

To analyze the current state of baby nutrition products based on fruit and vegetables, and the results of authors’ research in order to introduce their developments to industry. The enterprises of canning industry of Krasnodar region produce annually 350 thousand tons of canned fruits and vegetables, and their assortment is more than 250 kinds of items. Canned fruits and vegetables for baby food are produced from Kuban natural raw materials by the following companies: LLC "Organic Agroprodukt", LLC "Fine Food", LLC "Fabrica Zdoroviya", JSC "Syrodel", the branch of JSC "Experimental Plant" Lebedyansky".

The plant of children's canned meat "Tikhoretsky" operates in the Krasnodar region. This is the main producer of beef nutrition for small children in Russia, which accounts for 60% of children's canned meat market. "Tikhoretsky" produces 14 kinds of meat and meat-vegetable canned food for children at the brand of "Tema". The plant's capacity is 35 tons of finished products per day. The dairy plant "Labinskiy" manufactures its products at well-known brands such as: "Prostokvashino", "BioBalance", "Aktual" and "Tema". The production capacity is 300 tons of processed milk per day.

In Krylovskaya village, Leningrad district of Krasnodar region a new plant for production of fruit and vegetablebased baby food has been built recently. It is LLC "Kombinat Detskoye Pitaniye". It is planned to produce dry dairy-plant mixtures packed in plastic bags with a barrier layer and fruit puree and fruit - vegetable canned food for children from three months and older with consumer packing to glass containers of 100 milliliters according to the technology developed by scientists and specialists of the State Scientific Institution "Krasnodar Research Institute of storage and processing of agricultural products storage and processing".

The factory produced experimental batches of products (11 items). Currently the demand for manufactured types of baby food products is being studied in order to determine the volume of production in 2016.

We examined the development of production of baby food in Russia. It should be noted that the baby food segment of the grocery market is growing fast, both in the world and in Russia. This is explained by the growth of the birth rate, the growing care of parents about diverse nutrition of high quality, the change in living conditions connected with increasing social activity of parents and etc. According to the portal of the international business cooperation in Russia there was growth in sales of children's canned food by 11.6%, from 172.4 to 192.3 thousand tons in the period of 2006 – 2010 [1]. The share of canned fruit accounted for more than 50%, the share of children’s mixed puree - almost 21% of canned food. According to opinion of experts, the main feature of the baby food is constant expanding of the range of products on the basis of scientific recommendations and consumer priorities for the modern market.

The share of imported products exceeds more than 6 times the share of domestic production in Russian market of baby food. The following international companies dominate among the imported products of baby food: Nestle and Hienz, Abbott Laboratories company, Mead Johnson, Gerber (USA), Danone (France), Nutricia (Holland), International Nutrition Company (Denmark), Semper (Sweden), Valio (Finland), Fruktal, Kolinska (Slovenia), Hipp (Austria), Humana (Germany), "Bellakt" (Belarus). The smallest share of imported products for baby food is in the segment of fruit and vegetable juices, liquid and pasty dairy products.

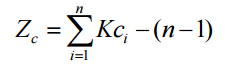

In 2015, the volume of baby food market in Russia has grown in comparison with 2012 by 47%. According to BusinesStat expert agency the Russian export of baby food products will be increasing during next few years (Figure 1).

At the same time Russian producers also export their products mainly to the CIS countries: Ukraine, Kazakhstan, Azerbaijan, Kyrgyzstan and others. The experts noted the growth of consumer confidence in the products of Russian producers, who offer high quality products at cost 1.5-2 times cheaper than from foreign competitors.

The main Russian producers of the baby food market are: СJSC "Plant of children's canned meat "Tikhoretsky", which is the part of "Danone's Group - Unimilk", JSC "Vologda baby food factory"(Vologda), County State Unitary Enterprise "Ekaterinburg City Dairy Plant number 1 (Ekaterinburg)", JSC" Plant of baby milk products (Moscow) ", JSC " Baby food "Istritsa - Nutricia", CJSC "Faustovo" (Moscow region), JSC Lebedyansky EKZ, Pepsico, JSC "Petmol", LLC "Baby food and food concentrates plant "(Saint-Petersburg).

In all countries the baby food manufacturers pay special attention to product safety. For example, the firm Semper (Sweden) uses only environmentally-friendly Swedish raw materials - genuine natural products: vegetables, fruits and grains, grown on soils that are absolutely free of chemical fertilizers, and harvested without preservatives. As for milk and meat products they should be received from animals without use of artificial additives, antibiotics, hormones.

Before entering into the production the raw materials are subjected to thorough check-up for compliance to regulatory requirements (bacteriological and toxicological control, testing for nitrates and nitrites, heavy metals, physical and chemical and organoleptic evaluation and others.). Finished products are undergone to careful analysis for compliance to quality and safety. One of the main requirements for manufacturers of baby food is a certificate of conformity of production and the products to standards, developed on the basis of the Alimentarius Codex adopted by the International Commission of FAO / WHO. "The regulations of the Code relate to: hygiene and nutritional value of food, including microbiological criteria, the requirements for food additives, pesticide residues and veterinary drugs, contaminants, labeling and appearance, as well as sampling and risk assessment methods" (the Code Commission Alimentarius Commission, Joint FAO / WHO Programme for food standards).

Experimental PartThe existing national and international experience was carefully analyzed during preparation for the establishment of domestic production of fruit and vegetable baby food in Krylovskaya village, Leningrad district of Krasnodar region. The results of this analysis became the basis for the adoption of technological, technical and organizational solutions of creators of this unique enterprise. Non-standard equipment for the enterprise was produced at a pilot plant in the research institute "Mir-Prodmash" (Moscow).

While selecting the construction site for the plant in Krylovskaya village, Leningrad district of Krasnodar region, close attention was paid to environmental problems. The analysis examined and assessed not only the influence of the forthcoming economic activity of the enterprise on the environment of its location (air, soil, groundwater and surface water streams, flora and fauna, the nearest residential area), but also compliance of state environmental components to the high sanitary requirements to the territories in which the production of baby food must be carried out. In addition, it was taken into account that the company is focused on the production of baby food products mainly from raw materials of Kuban agricultural producers.

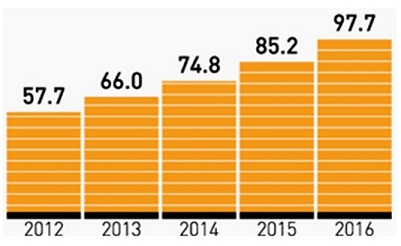

Krasnodar region is one of the leading Russian regions in terms of investment activity and it constantly ranks first in the Southern Federal District. The agrarian and industrial complex of the region is the leading branch of industry which attracts investments and determines the priority of regional economy. Natural conditions and resources of Krasnodar region, characterized by favorable soil and climatic conditions, allow to get better than in most of Russian regions yields of agricultural products. The total land area of Krasnodar region is more than 7.5 mln. hectares, including 3.8 mln. hectares of arable lands, of which more than 80% are black soils. The system of agro-industrial complex of Krasnodar region is conditionally divided into 5 zones (Figure 2).

Zone 1 (Northern) - a shallow wavy steppe plain, gradually rising from west to east. Here, the ordinary black soils (carbonate) are widely spread.

Zone 2 (central) has typical black and leached soil.

Zone 3 (southern, soils of foothill zone) has gray steppebrown forest - rendzina soils.

Zone 4 (zone preferably for rice growing) - soils of hydromorphic series, mainly alluvial meadow, meadowbog, marsh and saline and alkaline difference.

Zone 5 (predominant viticulture zone) - typical black soil and meadow black soil dominate.

The black soil is the most fertile soil of the region. It is common in plain zone 1 and 2. Humus stocks are not the same and vary from 783 tons /ha to 142 tons/ha and on an average compose about 456 tons/ha. The black soil is suitable for cultivation of all agricultural crops. 100 different species are cultivated in Kuban fields. Investigations of sanitary conditions of soil for agricultural purposes in accordance with GOST 17.4.2.01- 81 were held accordingly to Kuban land monitoring program. They showed that the territory of the region can be divided into areas with different qualitative assessment of pollution and namely: successful, selectively successful, little successful, unsuccessful depending on its functional specialization, the density of economic objects, the intensity of ecological and geochemical anomalies, and other factors [2].

The successful area includes fields for agricultural purposes in Beloglinsky, Novopokrovskiy and Krylovskoy administrative districts of Krasnodar region, within zones 1 and 2 of the system of agro-industrial complex, with a total area of over 12 thousand km2. There are no large industrial enterprises there, chemical warehouses of mineral fertilizers, plant protection factories, complex geochemical anomalies, which are the sources of pollution of the environment (air, soil, and groundwater).

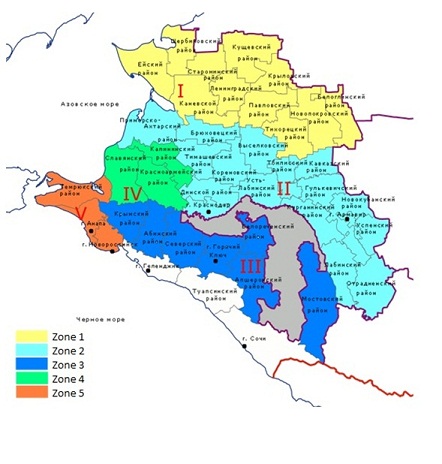

The assessment of the ecological state of the Krasnodar Territory land according to the total index of heavy metal pollution (Zc) was made by Professor Nazarko M.D. in 2014. It showed that there were agricultural areas of high local pollution in zones 1 and 2. To assess the ecological state of soils the guidelines for determination of heavy metals in soils of agricultural and crop production were used [3].

Total index of pollution (Zc) is determined by the formula:

n - the number of determined ingredients;

Ксi = Сi/Cф - metal concentration factor equal to the quotient of the mass fraction of the i-th element in the contaminated (Сi) and background soils (Cф). For general environmental characteristics of the main areas of cultivation of agricultural products (zones 1, 2 and 3) according to Zc, the number of defined elements in the soil is n = 25, for area characteristics according to elements of food safety n = 4 (Pb, As, Hg, Cd).

The indicator of environmental condition of Zc soils is calculated for all territory of zones 1 and 2 for 25 chemical elements: Cu, Zn, Pb, Ag, Bi, Sn, Mo, W, Co, Ni, Mn, Ti, V, Cr, Ga, Ge, P, Li, Be, Sr, Zr, Nb, Ba, As, Hg, as well as for 4 elements: Pb, As, Hg and Cd, which are the indicator of safety of plant products, according to the technical regulations of the Customs Union TRTS 021 / 2011 "About food safety" (hereinafter TR CU 021/2011), approved by the decision of the Customs Union Commission dated 09.12.2011, Nº 880 [4]. The same elements are normalized in the soil for Hygienic Standard (hereinafter HS) 2.1.7.2041-06 [5] and HS 2.1.7.2511-09 [6]. From the analysis of the results it is seen that in all three zones there are areas with high values of the indicator of ecological state of soils. Increased pollution of these areas with chemical elements is connected mainly with man-made influence on the environment, due to close location of residential areas, industrial plants, roads, etc. It is obvious that agricultural lands in these areas should be subjected to monitoring system in order to observe their ecological status in accordance with special developed programs.

According to Russian laws, children’s nutrition should be organized in accordance with the requirements of SanPiN 2.3.2.1940-05 [7] "Baby Food Organization", registered in the Ministry of Justice on the 03.02.2005, Nº 6295. This document defines requirements to:

Technical documents of children's food products production;

Raw materials and components used for production of baby food;

Ingredient and chemical composition of finished baby food;

Packaging of baby food and information printed on the label of product;

Technological equipment and technological processes in the production of baby food;

Organization and carrying out of production control at factories manufacturing baby food;

Production facilities of enterprises for production of baby food.

Results and DiscussionIt is obvious that the period of formation of baby food company in Krylovskaya village will take several years, but it is necessary to set goals and objectives, which will allow the company to take a leading position among Russian producers of canned fruit and vegetable-based baby food. To do this, they must make full use of world experience of creation of similar enterprises. The first step is to develop and implement HACCP system in the company - a risk analysis system and critical control points (Hazard Analysis and Critical Control Point systems), which will ensure the safety of products of baby food at all stages of the life cycle (production, storage, transportation, realization) and providing systematic identification, assessment and control of hazards that affect the safety of the manufactured product. Implementation of HACCP system in enterprises of members of the Customs Union is provided for TR CU 021/2011, Chapter 3, and Article 10. The basic principles of the HACCP system are stated in EU Regulation number 852/2004 of 29.04.2004 and include the following key statements:

Food safety must be guaranteed throughout its production chain;

The primary responsibility for food safety lies on manufacturer;

Implementation of procedures based on HACCP principles will allow the manufacturer to obtain safe food depending on the degree of responsibility;

The use of HACCP system will establish indicators for monitoring the production mode, based on scientific assessment of risk;

The application of HACCP system will ensure the production of food products according to EU standards, or at least equivalent to these standards.

The principles of HACCP system development are set out in the GOST R 51705-2001 "Management of food quality based on HACCP principles." During implementation of production processes (manufacturing) of food products associated with the safety requirements of such products, the manufacturer should develop, implement and maintain procedures based on HACCP principles stated in Part 3 of Article 10 of Chapter 3 TR CU 021/2011.

While forming the company it is necessary to implement procedures of Quality Management System (QMS) based on ISO 9000, Environmental Management System (EMS) based on the standards 14000 and ISO 22000 Food safety management (SMS) [8-10]. This will create a system of management of the entire production - economic activity of the enterprise with regard to product quality. This will develop policies, will set tasks and objectives, will identify effective ways of their solution. Certification of Quality Management System to ISO 9000 requirements will allow:

The company to be sure that manufactured products corresponds to regulatory requirements, market requirements and consumer expectations;

Consumers to be confident that they acquire the products with the quality corresponding to the regulations on quality and safety.

Implementing an EMS will allow the company to identify and control the environmental influence, monitor and improve its environmental performance, reduce costs for utilization of industrial wastes, reduce ecological payments, save energy and material consumption, and improve its image among consumers of products and public opinion, to increase competition of manufactured products. Implementation of SMS food is an integral part of the QMS, if we accept the definition that quality - is a measure of conformity of the product to its purpose.

ConclusionThus, only the implementation of the above mentioned measures will help Krylovskaya baby food plant to occupy its deserving place in the baby food market sector, as essentially the only measure of trust, recognized by the international community, is organization of the enterprise production based on the requirements and norms of the international standards ISO. The presence of QMS, SEM, SMS certificates characterizes the company as a stable and decent partner. However, experts of the enterprise should not forget that only high quality and low price provide competitive ability, stability and the possibility of enterprise survival in today’s market.

Figure 1: The forecast of the Russian export of baby food ($ Million).

Figure 2: The administrative-territorial division of the Krasnodar region in the system of agro-industrial complex.