Citation: Abel Pinto. A Methodology for Estimate Safety Barriers Effectiveness on Construction Industry Incorporating Uncertainties by the Use of Fuzzy Sets. Ergonomics Int J 2017, 1(1): 000101.

*Corresponding author: Abel Pinto, Industrial Engineering, New University of Lisbon, Avenida do Mar 30 5Esq 2825-476 Costa da Caparica, Portugal, Tel: 351 966870405; Email: abel.fnpinto@gmail.com

In occupational safety, prevention and protection usually involve the use of some sort of barriers. To estimate accurately safety barriers effectiveness it is of paramount importance to assure its performance and consequently keep the risks on adequate levels. But, what is safety barrier effectiveness? How to estimate it without statistical reliable data?

Estimate the effectiveness of safety barriers is a complex process that entails the consideration some quantitative parameters as well as perceptions which are fuzzy by nature and its assessment process involves complexity and uncertainty. A fuzzy approach is a better mathematical framework to estimate safety climate because uncertainty represented on fuzzy systems is a non-statistical uncertainty, which express vagueness, imprecision and/or ambiguity through fuzzy membership functions, and has a different nature from statistical uncertainty that is based on the laws of probability and is resolved through observations.

Departing from a literature review on safety climate, a set of factors affecting safety climate on construction sites were identified. A pole of six Portuguese construction safety experts contributed to adapt these factors to the Portuguese construction sites reality. The model was tested, conducting real case studies, by “peer” reviews by a pool of 11 safety experts from Brezil (2), Greece (3), Portugal (2), Turkey (3) and Bulgaria (1).

Estimate safety barriers effectiveness is of particular value to avoid the occurrence of work accidents that are costly in terms of the potential for loss of equipment, material, man-hours and human lives. The assessment tool developed and presented in this work seems suitable and easy to use by safety practitioners in construction sites.

Hence, in this work our objectives are: (1) to present a survey about concepts and performance of SB, (2) to overview how SB are used in construction industry and, (3) to provide a practical tool for assessing safety barriers effectiveness, using a fuzzy sets theory approach.

Keywords: Manoeuvres; Hazards; Vagueness and Ambiguity; Symbolic Barriers; Morphology; Safety Helmet; Safety Resilience; SB Effectiveness

High standards of occupational safety could be defined as the absence of accidents (and incidents), and therefore it means working with low risk. There are many contributing elements to ensure an adequate safety level at a workplace in the construction industry, such as technical and organizational safety features in an immediate level, and social factors and informal behaviour on a more remote level.

Prevention in occupational safety is based on mitigation (reducing the likelihood of occurrence of the undesirable event) and contingency (measures taken to decrease the impact of an event).

The means of prevention developed in occupational safety are numerous and include in particular:

a) Elimination of risk by design;

b) Limiting dangerous parameters from machines and processes;

c) Installation of isolating devices and equipment;

d) Blocking or prohibiting dangerous manoeuvres;

e) Analysis of safety failures;

f) Reducing the likelihood of breakdown or errors;

g) Individual protection;

h) Development and use of work procedures and;

i) Learning from dangerous incidenteIn the construction industry, prevention and protection usually involve the use of some sort of barriers.

Noted that barriers constitute only one of numerous possible prevention means but, on construction, they are extensively used, so to assure its effectiveness is of paramount importance.

Prevention consists in blocking or hampering initiating factors from triggering or contributing to an accident. Prevention and protection are always accomplished by using the four possible barrier systems, namely: physical, functional, symbolic and incorporeal, either individually or, in a more reliable way, in combination. Protection implies blocking or hindering accident´s consequences and involves the use of either physical or functional barrier systems [1]. Prevention is preferable to mitigation, in other words, risks should be reduced by reducing frequency of occurrence than by mitigation actions [2].

Although some kind of Safety Barriers (SB) have been used since the origins of our species to protect humans and property from enemies and natural hazards (e.g. energy sources floods, fires) there is no commonly/general accepted definition for them [3]. Different authors use different terms with similar meanings, such as: barrier, safety barrier, defense, safety defense, protection barrier, protection layer, safety critical element, safety function and safety system [3-10]. Without a clear definition and delimitation of the concept, a safety barrier could be any physical entity, any technical aspect (e.g. hardware component) or even any procedural or organizational element of the work environment, which aims to avoid, prevent, control, or mitigate undesired events such as work accidents and incidents. Moreover, European regulations and International standards enhance the importance of considering safety barriers to reduce the risk of accidents [11-15]. Reason [16] states that most of the accidents are due to a combination of an unexpected event with a dysfunctional or missing barrier, rather than to a single initiating action.

To ensure acceptable levels of occupational safety by preventing work accidents or minimizing their consequences, it is first of all necessary to identify all involved risks and its characteristics. Any SB design should only be attempted after completing the occupational risk assessment process thus ensuring its adequacy by function specificity. Guldenmund, et al. [17] states that each SB has to be designed (or ordered) according to particular specifications and must be built or delivered including installation and adjusted for use. Even for checking the performance of existing SB we need to know, in detail, the characteristics of the risks that intend to be reduced.

Another point to consider is that when we work with vague and/or imprecise knowledge or concepts, like effectiveness, adequacy, efficiency or performance, this cannot be accurately estimated by numeric values, so, a more realistic approach may be the use of linguistic assessment by means of assessing the problem fuzzy variables by linguistic semantic terms. Linguistic variable values are words or sentences in natural language and not numbers. As words are less precise than numbers, linguistic variables provide a mean to characterize phenomena that are too complex or too illdefined to be described in quantitative traditional way. In our case, risk assessment on construction industry is made, in an informal way, in natural language, using semantic terms like: too risky, risky, too dangerous, safe, very safe, or more specifically, in SB assessment by terms like: very adequate, inadequate, efficient, effective, nor effective.

Hence, identifying the main parameters involved in SB and estimate their effectiveness with some accuracy is of paramount importance to assure its performance and consequently keep the occupational safety risks on acceptable levels. But, what means SB effectiveness? How to measure (estimate) it without statistical data?

The main aim of this work is to contribute to answer these important questions. Specifically, the objectives of this paper are: (1) to present a short survey about concepts and performance of SB, (2) to overview how SB are used in construction industry and, (3) to provide a practical framework for assessing safety barriers effectiveness, using a fuzzy sets theory approach. It should be pointed that this work is based on several sources of knowledge: scientific literature; safety expert’s opinions on construction industry.

Safety Barriers Concept and TypesTo understand SB performance it is necessary, first of all, to understand what it is and how it works.

Overview of SBIn general, a barrier is any obstacle that obstructs the access, the progress or the spread of something. A common definition of SB is an obstacle (physical barrier), which function is to protect vulnerable targets (e.g. humans, environment, objects…) from hazards (e.g. dangerous energy) [18-20]. Later, this concept was extended to a “defense in depth” [21]; meaning a set of barriers (barrier system), located along the chain between hazards and possible accidents (or unwanted events), where each one (barrier element) is not sufficient to protect the target from the hazard, but working as a whole they can.

The term “defense barrier” was defined by Reason [22] as ‘‘the various means by which the goals of ensuring the safety of people and assets can be achieved”. The same author divided defenses in ‘‘hard defenses”, such as physical barriers and alarms, and ‘‘soft defenses” such as regulation, procedures, and training and refers to defense-in-depth as ‘‘successive layers of protection”. Comparing with other similar terms, such as: safety barrier, protection barrier or protection layer, defense concept has a wider range.

Accident investigations highlight the influence that management has on the SB effective operation. For example, MTO-analysis (Human, Technology, and Organization) applied in accident investigations, defined SB as ‘‘any operational, organisational, or technical solution or system that minimizes the probability of events to occur, and limit the consequences of such events’’ [23]. Svenson [5] pointed that is useful and very necessary to use a more precise terminology particularly to make a distinction between barrier systems and barrier functions . Barrier function, describes the modes by which it is possible generically to prevent or to protect against the hazards.

Barrier system, describes the means by which the barrier functions are fulfilled. Hollnagel [10] divide barrier systems, in four groups, by describing how which barrier functions are applied (what barriers are), namely:

Other SB division was presented by other authors of whom we highlight:

1. Duijm et al. [1], presents a division based on the action verbs to avoid, to prevent, to control, and to protect: (1) avoid intends to suppress all the potential causes of an event by changing the design of the equipment or the type of product used, (2) prevent intends to reduce the probability of an event by suppressing part of its potential causes or by reducing their intensity, (3) control intends to limit the deviation from a normal situation to an abnormal (and unacceptable) one and, (4) to protect intends to cover.

2. Schupp (in Sklet) [3] divided SB in two types related to “hazard targets”, namely: (1) primary barriers which are associated with primary hazards (hazards that could be directly harmful to humans) and, (2) secondary barriers which are associated with functional hazards (hazards that could indirectly become hazardous to humans).

3. Hale, Kjellén [24,25] divided SB in two types related to dependence on actions in order to achieve its function, namely: (1) passive barriers (do not requires any action to achieve its function in reducing risk) and, (2) active barriers (requires an action to achieve its function).

4. Guldenmund et al. [17] whom divided barrier systems, in two groups, hardware and behavioural elements, related with the risk assessment and management process:

A- Hardware related:

1. hazard (scenario) identification, barrier selection and specification;

2. monitoring, feedback, learning and change management;

3. design specification, purchase, construction, installation, interface design/layout and spares;

4. inspection, testing, performance monitoring, maintenance and repair;

B- Behaviour related:

5. procedures, plans, rules and goals;

6. availability, manpower planning;

7. competence, suitability;

8. commitment, conflict resolution;

9. coordination, communication.

Hence, in this work we follow the division proposed by Hollnagel (2008) [10] although it is not as simple and intuitive than the SB division proposed by Schupp (2004) or Duijm, et al. (2003), [1] because it seems more flexible, understandable and quite appropriate for the construction industry (because it is closer of what should be the good practice).

Safety Barriers on Construction IndustryConstruction sites usually have formal and informal SB elements in parallel, often overlapping. Sometimes it works as safety redundancy, which makes the safety system less vulnerable to changes and supports safety preservation (safety resilience). Ringdahl (2009) [26] describes this as a safety web rather than a distinct set of barriers. This feature can improve safety resilience but, on the other hand, this interaction between SB could decrease its effectiveness and/or create new risks, hence, it complicates the analysis and evaluation of the SB system implemented. Further, the analyst should understand well the SB elements and systems implemented, and its interactions, to understand its adequacy and availability. To achieve this understanding he will observe directly the site, and perform interviews with workers, foreman and engineers (to understand informal SB) and consultation of site documents (working procedures, reports of work accident investigation and others) in order to understand the reliability, robustness and resilience of the SB system.

As mentioned before, the first step for assessing SB in the construction industry is to determine which the most common accident modes are and which are the SB implemented to avoid it or to minimize their consequences.

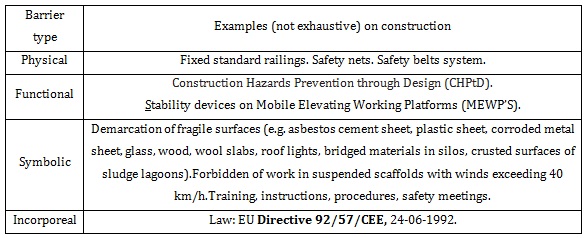

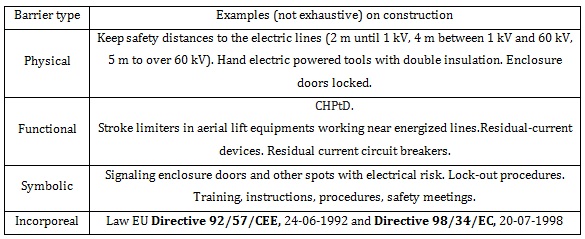

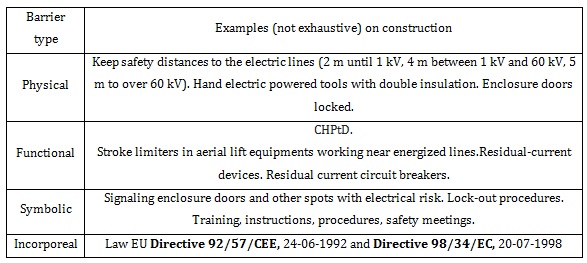

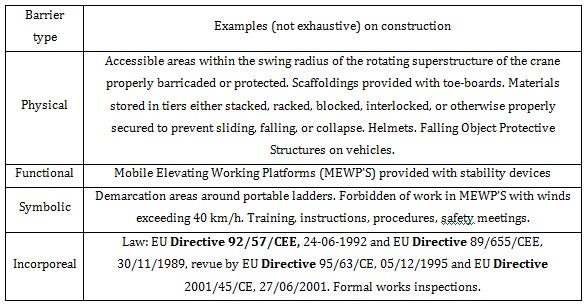

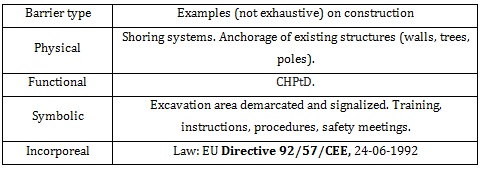

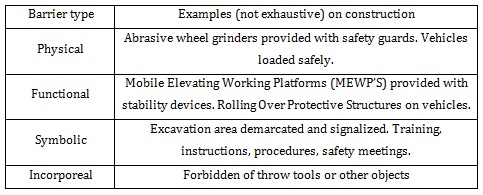

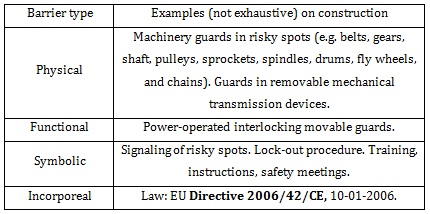

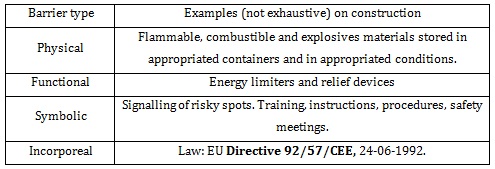

In (Tables 1-8) we summarize the most used SB for the eight most common accident modes found in construction sites, using the Hollnagel [10] division into four classes. This list is based on a preliminary list of accident modes for occupational accident scenarios, adapted for the construction industry [27-30].

Assessment of Safety Barriers Performance: A Fuzzy ToolIn this section we describe the proposed tool for SB effectiveness estimation. We start by presenting the basic concepts of fuzzy sets; second, we describe the proposed relative importance for the different SB types; third, we present the proposed “SB-Effectiveness-scale”; and, finally, we describe how to use the proposed scale and relative importance to estimate SB effectiveness.

Basics on Fuzzy SetsIn occupational safety, vagueness and ambiguity exist due to the limitations of our language and other factors such as ill-defined concepts, human variability and subjective information. Moreover, the nature of the work in construction sites is usually plagued with imprecisions, for example, On-site inspections generally use linguistic expressions rather than metrics to assess safety risks [31-33]. Additionally, legal records, statistical data and site documentation produced by companies are generally insufficient for analyzing the risks accurately. These facts increase the imprecision/uncertainty of the obtained results of occupational risk analysis, safety inspections or SB evaluations, and highlight the crucial need for flexible tools to handle uncertainty.

Fuzzy Set Theory was formulated in 1965 by Zadeh [34] and provides a mathematical framework for the systematic treatment of vagueness and imprecision. More specifically, FST may be viewed as an attempt at formalizing two remarkable human capabilities [34,35], namely: 1) to converse, reason and make rational decisions in uncertain environments; and 2) to perform a wide variety of physical and mental tasks without quantitative measurements.

A fuzzy set is said to include a boundary with a gradual contour, by contrast with classical sets, which present a discrete border, i.e. any object either belongs or not to a set. Formally, let U be the universe of discourse and u a generic element of U, a fuzzy subset A, defined in U, is one set of the dual pairs:

Where µA(u) is designated as membership function or membership grade of u in A. The membership function associates to each element u, of U, a real number µA(u), in the interval [0,1], where 0 means that it does not belong to the set and 1 means it “strongly” belongs, while intermediate values mean different degrees of “membership”.

An important concept in FST is the linguistic variable [36-38]. A linguistic variable is a variable that admits a set of labels (terms) of a natural language, each represented by a fuzzy set. An example is “temperature” that can be represented by the labels (cold, averagetemperature, warm) and each label will then be represented as a fuzzy set. Another example is our proposed transformation of Hollnagel [10] linguistic scale, as shown in Table 9, where we created a linguistic variable “Importance/weight”, which is represented by the discrete fuzzy set [high/1, medium-high/0.8, medium/0.6, low-medium/ 0.4, low/0.2] (details will be discussed in the next section).

It should also be pointed that FST deals with possible events and not with probable events. Possibility is the degree with which a variable may take a value and describes whether an outcome may happen while probability describes whether it will happen [39]. Hence, probability theory does not get displaced by FST, the two approaches are complementary. Probability theory is good for crisp but dispersed information, whereas FST is good for fuzzy but coherent information [39]. Moreover, probability theory requires that the complete set of possible outcomes must sum up to one, while FST allows freedom regarding the outcomes and their sum is not constrained by summing up to 1.

In summary the flexibility and adaptability of FST to handle ill-defined information constitute the motivation for our choice of mathematical framework for the proposed tool for estimating SB effectiveness.

Determination of SB Types Relative ImportanceAs shown in section 2 (Tables 1-8) all SB types are always related to a hazard and/or an accident sequence, in a preventive and/or protective way. Given their diversity and their specific characteristics, their assessment cannot be performed based solely on specific and strictly objective criteria but should also include some qualitative assessments, i.e. SB assessment should also rely on safety expert knowledge and experience as well as on the knowledge of the risks´ characteristics. However, the utilization of subjective judgement data based on expert´s opinions increases uncertainty. It is difficult to estimate probabilities related to perceptions because perception uncertainty are fuzzy by nature and probabilistic framework was developed to deal with random uncertainty [40]. So, fuzzy approach seems to be more useful to make estimates related to perceptions [41].

The main criteria that should be considered for SB assessment are: fitness to the purpose, fitness for usage, reliability, proper implementation, ease of comprehension (for symbolic barriers), knowledge of their applicability (for incorporeal barriers), robustness, functionality, response time, etc [3,9].

From our practical experience we elect, as the most important criteria for SB effectiveness estimation, the following:

It should be noted that for some types of barriers, not all the above criteria are relevant or necessary in order to describe the barrier performance.

An interesting definition of SB effectiveness is the ability (of a SB) to perform a safety function during a period, in a non-degraded mode and in pre-specified conditions [42]. Our definition of effectiveness applied to SB has a broader scope and includes the adequacy, reliability, robustness and specificity in order to produce the intended (or expected) result. Hence, our definition is: “effectiveness” evaluates the ability of a SB to achieve its purpose, when it is needed and how well it can withstand the variability of the environment and not lead to other accidents.

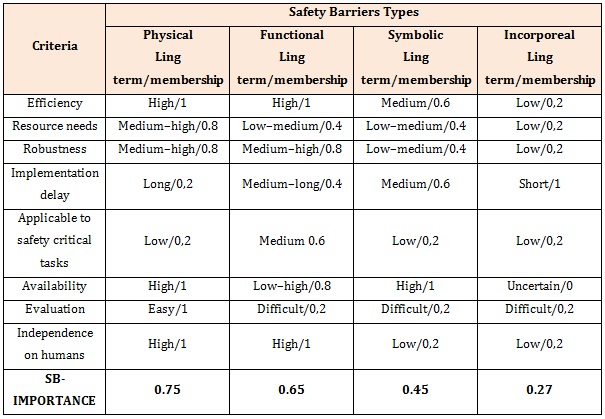

To evaluate a SB, we follow the criteria and evaluation levels defined by [10], about how barriers systems can achieve their purpose (Table 9). The set of 8 attributes according to Hollnagel [10] are: (1) Efficiency, which means “how well the SB meets its intended purpose”, (2) Resources (cost), which means “what is needed to design, develop, implement and maintain a SB”, (3) Robustness (reliability), which means “how well a SB can withstand the variability of the (work) environment”, (4) Implementation delay, which means “the time interval from conception to implementation of a SB”, (5) Applicable to safety critical tasks, which means “is a proper solution to risks on critical tasks”, (6) Availability, which means “whether a SB can fulfill its purpose when needed”, (7) Evaluation, which means “how easy it is to determine whether a SB works as expected, both during design and actual use” and, (8) Independence on humans (during operation), which means “the extent to which a barrier does not depends on human actions to achieve its purpose”.

Hollnagel [10] used a linguistic scale with eleven different semantic terms to evaluate the SB types regarding the set of 8 attributes, just described, as shown in Table 9. However, we can observe that some of the terms are similar in terms of attributes classification. For example (1) “high” in criteria Efficiency is similar to both “short” in Implementationdelay and “easy” in Evaluation (because they represent the same concept in terms of importance or weight of SBs; (2) “medium-high” and “low-high” have similar meaning when related with Robustness and Availability, respectively; (3) “medium” has no similar terms; (4) “low-medium” and “medium-long” again express the same concept in terms of importance for Resourceneeds and Implementation-delay, respectively; (5) “low”, ”long” and “difficult” have the same meaning for Efficiency, Implementation-delay and Evaluation, respectively.

In our proposal we assume the described similarity between the semantic terms for evaluating the 8 criteria of Hollnagel [10], regarding the different types of SB, to extend this study with a fuzzy approach. To start, we detemine a common relative importance by fuzzifying the above evaluation using just 5 discriminative terms (relative to the above similarity described). This fuzzification process implies the creation of a fuzzy membership function (Zimmerman, 2003), which in our case is a discrete fuzzy membership function. The defined discrete fuzzy set is:

IMPORTANCE-SCALE= [high/1, medium-high/0.8, medium/0.6, low-medium/0.4, low/0.2, uncertain/0].

The numerical values used in the membership function, took in consideration an equal division of the 0 -1 scale for the 5 discriminative linguistic terms of Hollnagel [10]. It should be noted that in fuzzy logic we could assume that “uncertain” is outside the fuzzy function (value 0) because we do not have any knowledge about its degree of belonging (i.e. it does not belong with any degree to the defined fuzzy set), while with probabilities this value would (in our view incorrectly) be 0.5.

After, defining the fuzzy set importance -scale we can determine the final importance/weight for each SB type using a simple averaging operator (by column) as depicted in Table 9. The calculation of the SBImportance, or weight of each SB type is the first step to estimate SB´s effectiveness; the remaining steps to determine the SB effectiveness are described in section 3.3.

It should be noted that Hollnagel [10] evaluation included both Personal Protective Equipments (PPE) and collective protection devices in the physical type. However, these two types of equipment’s have significant differences regarding efficiency, availability and independence on humans – hence they should not have been included in the same group. The SB effectiveness-scale that we propose in the next section takes into account this aspect.

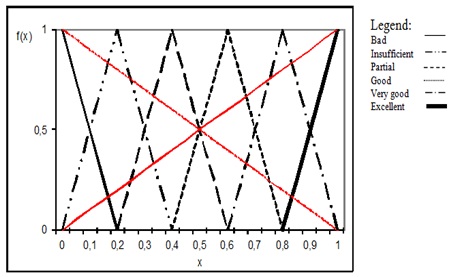

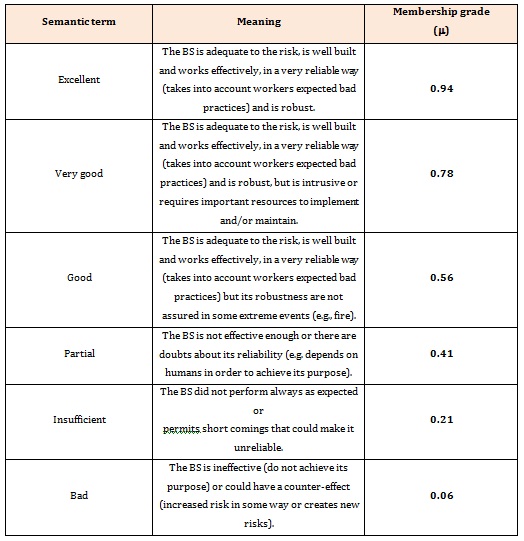

Determination of SB Effectivenes-ScaleAfter determining the relative importance of each SB type we will now define a linguistic variable to act as the scale for classifying the SB effectiveness. We start by creating a linguistic variable with six terms that are represented by triangular membership functions in the interval [0, 1], as shown in Figure 1. The six terms will allow a more user-friendly elicitation of information from the involved stakeholders (e.g. workers, safety experts, managers, among others) because the checklists with the criteria and alternatives (SB types) will be answered semantically as: (a) “excellent” (corresponds to triangle range [0.8, 1.0] in Figure 1); (b) “very good” (Figure 1 range [0.6, 1.0]); (c) “good”, (Figure 1 range [0.4, 0.8]); (d) “partial” (Figure 1 range [0.2, 0.6]); (e) “insufficient” (Figure 1 range [0.0, 0.4]); (f) and “bad” (Figure 1 range [0.0, 0.2]).

To simplify the rating and calculation process we now discretize this linguistic variable, by using a simple discretization method proposed by Chen and Hwang as presented in Marques [43,44]. Furthermore, information loss resulting from this discretization will not significantly affect the evaluation result as shown by Chen and Hwang [43]. The discretization process for the linguistic variable (Figure 1) is explained below

The discretization process starts by considering two fuzzy linear functions, a maximizing one µmax(x)(see red line on figure) and a minimizing one µmin(x)(see red dotted line on figure).Second, we determine the values of the intersection of the left side of each linguistic term with the minimizer and the right side of each linguistic variable term with the maximizer, such as:

And, finally, the membership grade for each linguistic term (T) is obtained through the expression:

After these calculations we can now propose a discrete “SB-effectiveness-scale”to be used in our tool, as shown in Table 10.

Observing Table 10 we see on the left the semantic terms to be used during the elicitation process by the analysts. On the center we see a description with the meaning of each term in the SB context (this explanation serves as guide for the analysts and can also be explained to the workers involved). Finally the right column includes the numerical scale that will be used in the calculation process to estimate the SB effectiveness.

As noted in section 3.2, there is a difference in effectiveness between PPEs and collective protection equipment and our proposed measure reflects this fact. Since PPEs depends on humans to achieve its purpose (and only offers limited protection to a part of the body of one worker), its maximum effectiveness will be classified as “partial” (never reach the “excellent”, “very good” or “good” levels). By the same reason (dependence on humans), work instructions and procedures, training, signalization, alarms, or more generally, for all symbolic barriers type the maximum effectiveness should be “partial”. Between “excellent” and “very good” there is no difference with regard (directly) to safety, the difference lies on resources efficiency and intrusiveness to the production process. An efficient and not intrusive SB have better acceptance at all organization levels.

In the next section we explain the process to obtain the estimation for SB system effectiveness, using the two determined measures: the relative importance of each SB (Table 9) and the SB-effectiveness-scale (Table 10).

Estimation of SB effectivenessFor obtaining an evaluation for any SB system the safety experts should follow the sequence of the possible chain of events, either by starting with the accident modes and going backwards or starting in the hazard and look forward to the probable work accident.

In general, for each accident mode, the analysis should be guided with questions such as:

To answer these questions, the analyst should check key points, namely: (1) SB design – including interfaces and work modifications required, (2) checking/supervision of construction and installation, (3) human factors of SB operation and maintenance – availability, commitment and competence of personnel, (4) inspections and maintenance programs, (5) supervision of maintenance tasks, (6) SBs management – including communication and coordination, conflict resolution and the existence of spares (when required) and, (7) risks review (including the SBs). Whose data can be obtained by direct observation and analysis of documents such as: a) SB project, b) accidents and incidents research reports, c) inspections and maintenance programs and reports, etc.

In this article we do not present more details about defining a checklist with questions to obtain the classifications for effectiveness of SB because our focus is on defining a tool for estimating SB effectiveness. Our proposed tool can be used with any type of checklist.

To obtain the estimate of the SB system effectiveness, we need to aggregate the analysts classifications for each SB type using the previous scale. However, the choice of aggregation operator is a dificcult task since it is a context-based question.

Aggregation operations on fuzzy sets are operations by which several fuzzy sets are combined in some way to produce a single representative either fuzzy or crisp set [45]. There is no simple rule to choose the adequate operator among the existing variety, but Zimmerman [46] pointed eight important criteria that can be helpful to select the appropriate operator, namely: axiomatic strength, empirical fit, adaptability, numerical efficiency, compensation, range of compensation, aggregating behavior and required scale level of membership functions. Beliakov and Warren [47] added another criteria: semantical clarity.

In occupational safety risk assessment little is known about how the factors should be fuzzified and aggregated. Safety experts provide their perceptions about the behavior of the model and the corresponding empirical data by considering practical cases. Due to the absence of set-theoretical criteria, the aggregation operator was chosen using what seem to be the most adequate qualities for risk assessment: (1) empirical fitness; (2) adaptability; and (3) semantic clarity.

The reasoning used for SB regarding these qualities is:

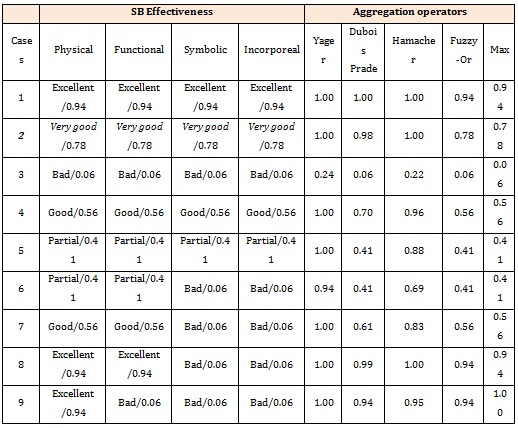

Using the above quality criteria and corresponding reasoning for SBs, we know that we need an operator from the class of “Union” (OR) because we want a synergistic positive effect. The positive synergy allows us to express the added value of having more than 1 SB type in construction sites, i.e. if we have 2 SB their “sum” should be bigger than the simple arithmetic sum. From the most known union operators we tested the following: Max, Yager, Dubois&Prade, Hamacher and Fuzzy–Or [46] (Table 11). In fact, multiple SB works like a set of layers whose result is always better than the worst barrier.

So, observing Table 11 it is clear that:

1. The Yager operator does not fit because it is not sufficiently discriminative (e.g. only cases 3 and 6 have aggregated effectiveness levels different from 1!);

2. The Max and the Fuzzy-or operators do not display any synergetic effect, i.e. it always chooses the highest classification achieved for all 4 cases disregarding any compensation for having more than one with good classification;

3. If all the SB are “excellent” , the result should be higher than the average of a MAX . Yager, Dubois&Prade and Hamacher operators fit this empirical knowledge (case 1= 1);

4. If all barriers are “bad”, the result should be “insufficient” but should encompass the added value (synergetic effect) because a set of four bad SB have a better performance than one single bad SB. In this case only the Hamacher operator fit this empirical knowledge (case 3= 0.22);

5. If the four barriers are “good”, the result should be “excellent” (though somewhat less excellent than four “excellent”). Again only the Hamacher operator fit the empirical knowledge (case 4=0.96);

6. If we have two barriers “partial” and two barriers “bad”, the result should be “good” due to the synergistic effect of this combination of SB working together, resulting in a “good” performance. In this case only the Hamacher operator fit (case 6 = 0.69), since Yager results in “excellent” (0.94) and the others result in “partial” (0.41);

7. If we have two barriers “excellent” and two barriers “bad”, the result should continue to be “excellent” but with a slight added reward (synergistic effect of two “excellent” SB) . Yager and Hamacher operator fit this requirement (case 8 =1);

8. If we have one barrier “excellent” and three barriers “bad”, the result should still be “excellent” but with a lesser degree because the safety level - related to the risk- decreases, i.e. in this case the result should be somewhat less excellent than the previous one (point 7). Dubois & Prade, Hamacher and Fuzzy-OR operators fit this empirical knowledge and present an adequate discriminative effect (0.94 and 0.95 in case 9).

From the observations made on points 1-8 above, it is clear that Hammacher union operator is the one that best answers the quality criteria for SB effectiveness estimation and, consequently, the one selected for our tool.

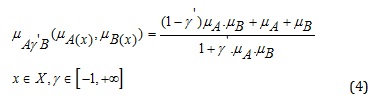

Formally, the Hammacher-OR operator is:

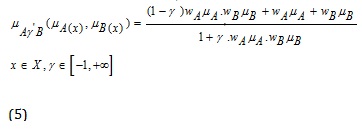

However, since we also need to incorporate the relative importance for each SB type, as described in section 3.2., we selected the version with relative importance weighting, such as:

4.8. Illustrative Examples of SB Effectiveness Tool

Usage

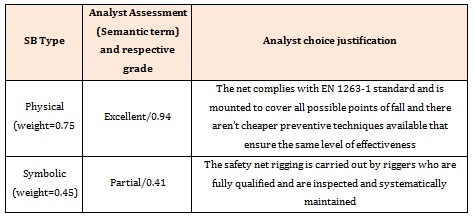

In this section we will use a safety net example. Safety Nets are barrier systems because their effectiveness depends on the physical device and the riggers training, inspection and maintenance procedures. So, physical effectiveness is “excellent” if the net complies with EN 1263-1 standard and is mounted to cover all possible points of fall. If there are cheaper preventive techniques available (and to ensure the same level of effectiveness), effectiveness should be considered “very good”. If the site is located in a climate adverse place, e.g. snow and strong winds, its effectiveness should be “good” (because reliability may be compromised). If the net does not cover one spot (e.g. in a corner or a pillar…) or is fitted far away from the work position, effectiveness should be “partial”. If the safety net does not comply with any recognized and accepted standard (even if its robustness seems to be adequate) effectiveness should be “insufficient”. If the safety net possesses some defects (color changes, broken wires or ropes…) effectiveness should be “bad” (because robustness may be compromised).

If the safety net rigging is carried out by riggers who are fully qualified and are inspected and systematically maintained, symbolic effectiveness should be “partial”. If the safety net is not inspected or systematically maintained, within appropriate intervals symbolic effectiveness should be “insufficient”. If the safety net rigging are carried out by riggers who are not qualified symbolic effectiveness should be “bad”.

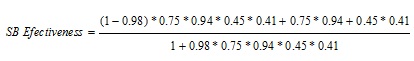

Now considering an illustrative example with two SB types, a physical one and a symbolic one, and by direct observation the analyst classified the 2 SB, as depicted in table 12. Then using the respective relative importance/weights (from Table 9 and reproduced in Table 12) and the selected weighted Hammacher operator (equation 5) with a parameter, ƴ = 0.98 the result for the SB effectiveness estimation is

SB Efectiveness = 0.79.

Since this SB system is the “sum” (aggregation) of two safety barriers that contribute to mitigate the same risk, one excellent and important and one partial and less important, the effectiveness result is “very good” = 0.79. This result matched the conservative empiric expert knowledge of the analyst.

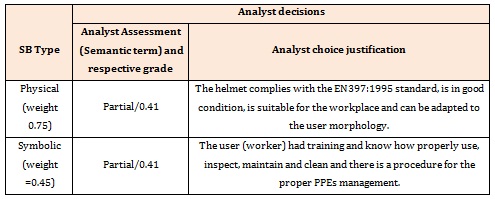

Now, let us considering another example, the use of safety helmets to protect against falling objects, which is also a barrier system. If the physical device complies with EN397:1995 standard (or other similar), is in good condition, is suitable for the workplace and can be adapted to the users morphology, so physical effectiveness should be “partial”. If the helmet has small defects such as: color changes, small changes in structure (small holes for ventilation, for example), paintings (names or something else), stickers (some manufacturers advise against), etc or is not suitable for the workplace or can’t be adapted to the users morphology effectiveness should be “insufficient”. If the helmet does not comply with EN397:1995 standard (or other similar) or has defects such as fissures effectiveness should be “bad”. If workers had training and know how properly use, inspect, maintain and clean and there is a procedure for the proper PPEs management symbolic effectiveness should be “partial”. If workers didn’t inspect, maintain or clean the helmets regularly (but use them and had training) or the company don’t manage PPIs properly (although a procedure) symbolic effectiveness should be “insufficient”. If workers didn’t had training or there are no procedure for PPEs management symbolic effectiveness should be “bad”. Table 13 depicts the classifications for this example, considering two similar “partial” classification of SB elements (0.41) but since they have different importance weights, when applying the expression 5 we obtain SB Effectiveness= 0.47, i.e. it is classified as a little better than a “partially safe” SB system. This result also matches the conservative empiric expert knowledge.

Another example of SB widely used at construction is the fall arrest system. Although it is a PPE that protects the entire body their effectiveness is not the same as an collective protective equipment. The use of this equipment carries the risk of orthostatic syndrome [48- 49]. If all physical device (harness, ropes, lanyards, shock absorbing…) complies with EN361 standard (or other similar), are in good condition, are suitable for the workplace, can be adapted to the users morphology and there are sufficient and robust anchor points to which workers could fasten their personal fall arrest equipment, so physical effectiveness should be “partial”.

If the harness (or accessories) has small defects such as: color changes, small changes in structure geometry etc or is not suitable for the workplace effectiveness should be “insufficient”. If the harness (or accessories) does not complies with EN361 standard (or other similar) or has defects or there aren’t sufficient or robust anchor points to which workers could fasten their personal fall arrest equipment, effectiveness should be “bad”. If workers had training and know how properly use, inspect, maintain and clean and there is a procedure for the proper PPIs management and work at height, including emergency rescue, symbolic effectiveness should be “partial”.

If workers didn’t inspect, maintain or clean the equipment daily (but use them and had training) or the company don’t manage PPEs properly (although a procedure) symbolic effectiveness should be “insufficient”. If workers didn’t have training or there are no procedure for PPEs management or emergency rescue is nor assured, should symbolic effectiveness be “bad”.

Incorporeal barriers, such as legal requirements (or others), should be “excellent” if the company identify, access and apply legal or other requirements, keep this information up-to-date and communicates, timely, relevant information about these requirements to persons working under its control and other interested parties, in an efficient way. If the company doesn’t have an efficient procedure, incorporeal BS should be considered “very good” (because, could reach the same result with less resources). If the company identify, access and apply legal or other requirements, keep this information up-to-date but not communicate, timely, relevant information, effectiveness should be “good”. If the company identify, access and apply legal or other requirements, keep this information up-to-date but not communicates relevant information, effectiveness should be “partial”. If the company don’t identify, access and apply legal or other requirements, keep this information up-to-date and communicates, timely, relevant information, timely and in a reliable way, effectiveness should be “insufficient”. If the company don’t identify or access or apply legal or other requirements or don’t keep this information up-to-date or not communicates, timely, relevant information effectiveness should be “bad”.

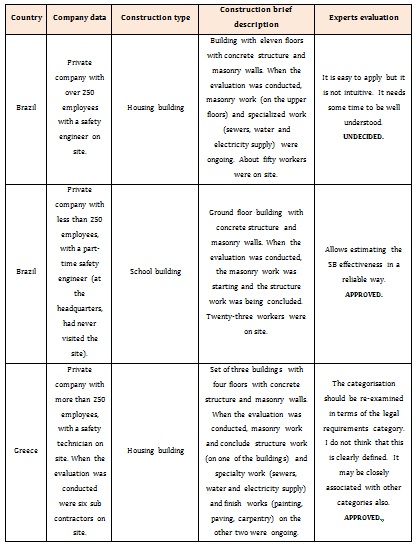

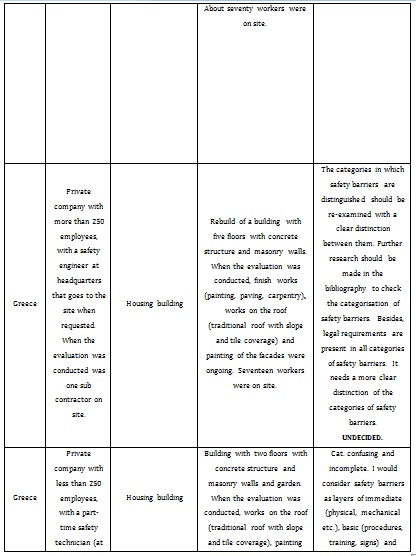

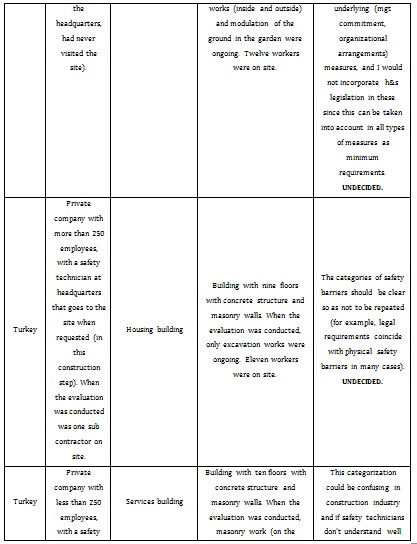

This model was tested by application on real sites and results “peer” review by a pool of 11 safety experts from Brezil (2), Greece (3), Portugal (2), Turkey (3) and Bulgaria (1). This way seems appropriate to evaluate the rationality of the framework structure and the adequacy to which the safety climate is scored. According to Habermas the rationality of science stems not from any objective, external measures, but from agreed formalisms involving transactions between knowledgeable human beings and agreement between them about what can be considered to be “rational”, given the base of available knowledge and experience.

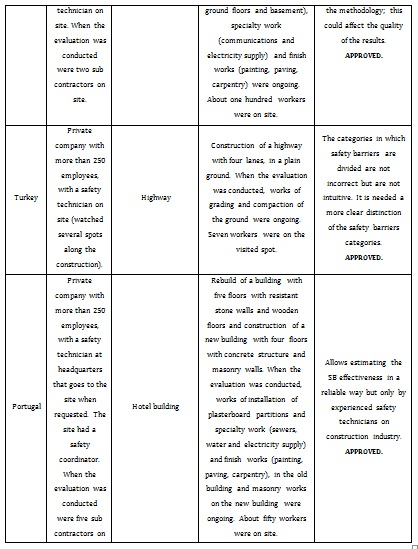

In each of the referred countries, the model was first presented to the safety experts; the features and the rational underlying its development were explained. Second, the model was applied to real construction sites and the safety experts were requested to verify if the results correspond to their empirical knowledge, by a 5- point semantic Liker scale questionnaire (Strongly Approved, Approved, Undecided, Disapproved and Strongly Disapproved). Questionnaires were taken individually. In general experts agreed with the model results (63,6% Approve and 36,4% Undecided) and all have made comments, which are summarized in the table 4.

Despite the differences by their local environment and culture, there were no substantial differences in the pattern of responses of the construction safety experts from the different countries (and continents).

The main causes of criticism are about the SB division. Some of the experts consider the categorization confusing and incomplete and stated that should be re-examined to make a clear distinction between types and they consider that legal requirements are present in all categories of safety barriers. They suggested to consider safety barriers as layers of: immediate (physical, mechanical etc.), basic (procedures, training, signs) and underlying measures (management commitment, organizational arrangements), and should not incorporate H&S legislation since this can be taken into account in all types of measures as minimum requirements. This criticism seems to be rooted in the difficult intuitiveness of the proposed division. When well understand this division in the most appropriate to use on construction industry.

The main advantages pointed by the safety experts were the linguistic scale measurement and the calculation process because it is intuitive, user-friendly and quick to apply.

ConclusionIn this work we presented a versatile tool for estimating the SB effectiveness in construction sites. The proposed tool is based on fuzzy ratings to assess the features than can affect the SB effectiveness by addressing the following attributes (1) Efficiency, (2) Resources needed (3) Robustness (reliability), (4) Availability, and, (5) Independence on humans (during operation).

The fuzzy approach seems quite suitable to deal with the vagueness and imprecision that is ever present in an SB effectiveness estimation and allows to mimic human decision making.

The advantages of the proposed tool are:

Disadvantages are:

In summary, we believe that the proposed tool may reduce the subjectivity in assessing SB effectiveness by estimating their ability to achieve their purpose, ie., how well they can withstand the variability of the environment and not lead to accidents. Moreover, we presented illustrative examples to better clarify the usage of the proposed tool and how to interpret the results. In addition, since our proposed tool is quite versatile and adaptable, we believe it contributes to advances in determining the quality of the overall occupational risk assessment in construction sites.

Finally, the presented tool was developed for construction industry, however, with some minor adaptations, may also be applied in other industries (e.g., process industry).

AcknowledgmentsThis work was funded by the Portuguese Foundation for Science and Technology, Scholarship No. SFRH/BD/39610/2007.

Figure 1: Linguistic variable for measuring SB effectiveness.

Table 1: Safety Barriers for Falls.

Table 2: Safety Barriers for Contact with electricity.

Table 3: Safety Barriers for Struck by Moving Vehicle.

Table 4: Safety Barriers for Injured by Falling Objects.

Table 5: Safety Barriers for Cave-ins.

Table 6: Safety Barriers for Hit by rolling/sliding object.

Table 7: Safety Barriers for Contact with Machinery Moving Parts.

Table 8: Safety Barriers for Fire or explosion.

Table 9: SB types ‘evaluation, According to Hollnagel (2008) and its Fuzzification.

Table 10: “SB-Effectiveness-scale”.

Table 11: Aggregation results.

Table 12: Illustrative example of SB effectiveness for Safety Nets.

Table 13: Illustrative example of SB effectiveness for Safety Helmets.

Table 14: Summary of the expert’s opinions.

Chat with us on WhatsApp