Citation: Dakeev U and Pecen R. Investigation of Spatial Orientation of Freshmen Level Engineering Students with the Introduction of Additive and Subtractive Manufacturing. Ergonomics Int J 2017, 1(3): 000116

*Corresponding author: Ulan Dakeev, Assistant Professor, Industrial Technology College of Engineering, Texas A&M University, Kingsville, 1005 N. Armstrong, 105, Kingsville, TX, 78363, USA, Tel: 361-593-2610; Email: ulan.dakeev@tamuk.edu

Generic introduction to computer aided design class in industrial/engineering technology involves the introduction to sketches, three-dimensional model development, and the generation of blueprints for the models. In some cases, the students learn the assembly and simulation for stress or aerodynamics analyses if the time is sufficient. Industrial and Engineering technology students rarely learn 3D printing or CNC in their CAD classes. Some institutions have advanced level computer aided design elective classes that teach students advanced techniques and skills within the software, however, the CNC and 3D printing is still left out of the curriculum. The advancement of technology requires both industrial and engineering technology students to possess 3D printing and CNC skills to stay competitive in the job market. This study reports on the redesign of an introductory CAD course in industrial technology department to involve regular CAD concepts, development of 3D printed parts, and manufacturing in CNC. This study is comprised of multiple phases: 1-Introductory CAD, 2- 3D printed CAD, and 3-CNC CAD. The participating students will receive a spatial test on a pre-defined object at the beginning of semester. During the phase 1 the students will have developed basic 3D modeling skills and reproduced the pre-defined part, where the researchers will record the influence of CAD software on the spatial orientation. The second phase involves students to 3D print their pre-defined part and inspect physically to compare with the original design and complete the spatial test. During the 3rd phase, the students will manufacture their parts in CNC, analyze the result, and complete the spatial test. All collected data will be statistically compared to investigate which of the phases influences student spatial orientation most. Authors believe that the introduction of 3D printing technology and CNC to an introductory computer aided design course will improve student spatial orientation and will better relate their degree to engineering practices.

Keywords: Aided Design; 3D- Modeling; CNC Manufacturing; CAD Course

Economic growth of a country is directly linked to the urbanization, which highly depends on the Computer Aided Design (CAD) skills. These CAD software programs are used to develop three dimensional (3D) solid models that can be transformed to blueprints, 3D printed prototype parts and CNC manufactured products. Moreover, a variety of application CAD software has been developed in recent years to improve productivity and equity in both manufacturing and construction [1]. Researchers have repeatedly indicated that the additive manufacturing will grow further, despite all the potential risks, therefore, improvement in CAD courses is one of the main priorities in academia [2,3].

In the twenty-first century, one of the most important factors that contribute to a newly graduating engineering students’ competitive advantage in the job market is the spatial orientation attributes. This study examines the influence of additive manufacturing (aka 3D printing) and subtractive manufacturing (CNC) in students’ understanding of the three-dimensional environment. An introductory level CAD course was redesigned to investigate the significance level between 3D printing and CNC manufacturing in paired sample tTest analysis.

Conceptualization in the Computer Aided DesignFast-flowing time in business requires companies to introduce their product to market in short period of time since the total revenue is the amount of money that a company receives from the sale of finished goods. Larson and Gray (2014) [4] indicate that a three month of delay in the market loses 33% percent of income. Companies attach increasing value to train employees for innovative performance, whereas educational institutions foster creativity and innovation in students [5]. Augusto (2013) stated that a cognitive representation is a hypothetical internal cognitive symbol that represents an external reality that makes use of such a symbol [6]. Therefore, the CAD drafters draw on their personal experiences and knowledge to formulate new design concepts [7]. CAD representation serves as a means of communication and exploration among design engineers, suppliers, and customers. Previous studies indicated that effective visual representation of an end product is far more beneficial for solving problems and completing design tasks compared to descriptions in narrative forms [8,9].

Students, in computer aided design courses, should develop engineering practices such as drawing upon abstract concepts to solve problems and meet customer specifications during the brainstorming group sessions. Jonson (2005) stated that both abstract and figurative representations are crucial in drafting [10]. Macomber and Yang (2011) confirmed that sketching during the product development improves the quality of the design [11]. However, the concept design stage may require more diverse approaches to the stimulation of spatial orientation, which is required to visualize the threedimensional concept of the prototype.

Graphics software is becoming increasingly easy to use. The dynamic rendering function of CAD software helps students understand complex structural design and convert design concepts into prototypes more efficiently. Incorporation of virtual reality technology has increased the popularity of 3D modeling for product development, and it has become a medium for design objectives, concepts, and product representations.

Design and ImplementationIn total, 35 undergraduate students from XXX University were recruited to participate in the present study. Among the participants 20% (n=7) were female, and 80% (n=28) were male students. The participants volunteered to participate in the spatial orientation test during spring.

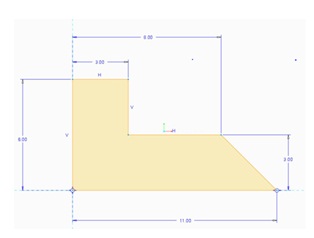

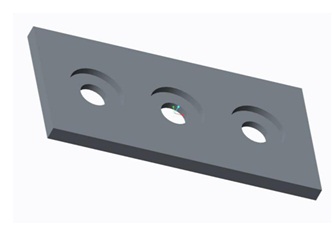

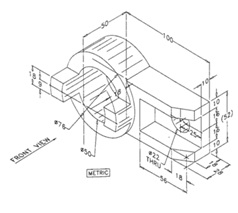

2017 Undergraduate Computer Aided Design CourseA pretest and post-test survey data were collected to investigate the significant difference between groups when both 3D printing and CNC manufacturing were introduced. The first stage of the study involved the participating students to complete a spatial orientation test from 123test.com at the beginning of spring 2017 semester. Conventional introductory tutorial-based lectures were demonstrated for the two-dimensional sketch and three-dimensional modeling such as extrusion, revolves etc. using Creo Parametric software before the students administered the test. Creo is one of the most popular 3D modeling software in the market and provides one year of free license to students. A sample assignment for both and sketch and extrusion are illustrated in Figures 1 & 2.

Figure 1 illustrates the basic 2D sketch in the introductory CAD course, where students are explained that the three-dimensional features of a prototype part is developed from the two-dimensional sketch.

Figure 2 illustrates the basic extrusion parameters within Creo software. This exercise includes both additive and subtractive extrusion of materials. By the end of first four weeks into the semester, the students have developed independent 3D modeling skills to generate parts in moderate complexity as shown in Figure 3.

The second stage of the study was comprised of two sections, which included an introduction to additive and subtractive manufacturing processes with 3D printing and CNC. The students were assigned to develop a 3D model of their choice (with the instructor’s approval) and develop the product with the 3D printer. The project assignment required at least three unique parts to be assembled after the parts had been printed as shown in Figure 4.

Out of 35 participating students, 32 completed their individual projects on time, while three students needed extended time frames to ensure the accuracy of the submission. One of the challenges of the project was that the students spent an extended period of time in orienting the features of the models within the software. For example, one of the students developed a fidget spinner with its components and the unique ergonomic design on the right side of the spinner was modeled upside down. Class discussion of this fidget spinner project enabled additional students to revise their models in the software. Overall, this project was interesting and engaging for the class and 100% of the participants submitted their completed work successfully.

The CNC section of the project involved groups of 3-5 students to work together to develop a project of their choice with the instructor’s approval. Each student needed to develop an individual 3D model of the part, generate a tool path for the work place; CNC cut the work and assemble the final result as shown in Figure 5. Some groups decided to develop plagues (Figure 6), which could not be assembled as a final assembly, but individual CNC practice assignment was fulfilled.

Data AnalysisA total number of 35 students participated in the project. Nineteen (19) students completed the spatial test orientation survey after the individual 3D printing project. Additional sixteen (16) students’ survey results were recorded after they have completed their CNC group projects. Although the authors are not comparing the differences between the 3D printing influences versus CNC, it is interesting to note that the two groups’ survey results were different in both scenarios.

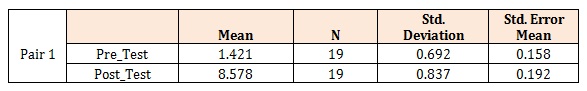

The following pretest- post-test tables (Table 1) reveal the descriptive and paired sample t-Test outcomes from SPSS statistical package. Out of 19 participating students in 3D printing, 15.78% (n=3) were female and 84.21% (n=16) were male students.

Table 1 illustrates that there is 7.157 difference between pretest and posttest scores in mean values, indicating that the students developed significant (Table 2) amount of understanding in spatial orientation.

Table 2 illustrates that there is a significant difference between the pre-test and post test scores (alpha level =0.05> p=0.000). The outcome of SPSS result showed there was a 75% correlation between the integration of the 3D printing practice in CAD class and the spatial orientation at 95% confidence interval.

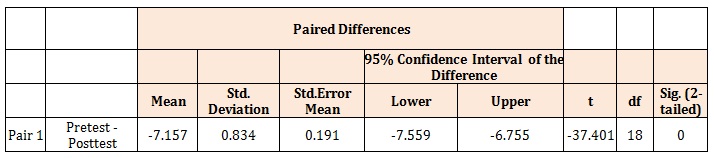

The second section of the project development include the results from 16 total participants with 25% (n=4) female and 75% (n=10) male students. The group project assignment required to develop individual products for the final assembly after CNC manufacturing processes. Tables 3 and 4 report the pretest and posttest outcomes from SPSS.

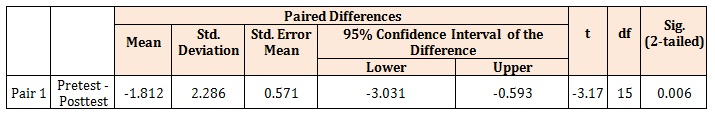

Paired Samples StatisticsThe descriptive statistics on Table 3 shows that there is 1.812 mean differences between the pretest and posttest outcomes. As discussed above, the second cohort of test takers scored higher in the pretest (mean 1=1.421 (Table 1) < mean 2 = 5.875 (Table 3)). Additionally, Table 4 shows that there was a significant difference (alpha level=0.05> p=0.006) between pretest and posttest results, at 95% confidence interval, with 59.6% between the integration of the CNC practice in CAD class and the spatial orientation at correlation outcome.

Paired Samples TestTable 4: Paired sample t-Test for CNC manufacturing.

ResultsThe present study compared the survey mean values between students, who modeled part without 3D printing involved, individual model development with 3D printing, and model development within the group with CNC manufacturing. The findings indicated that introduction of 3D printing and CNC manufacturing moderately and positively correlated with the spatial orientation learning. Moreover, the effect of 3D printing and CNC manufacturing significantly improved students’ learning in spatial orientation. The findings also suggested that 3D printing mean was slightly higher than the CNC manufacturing; however, the initial mean value of pretest scores of the second cohort (CNC manufacturing) was higher than the 3D printing cohort.

The purpose of the study was to investigate how the introduction of additive and subtractive manufacturing in introductory level computer aided design courses influenced the spatial orientation learning of the undergraduate students. Future qualitative and quantitative research should examine how to retain the positive effect of both processes while introducing both methods separately and comparing which process has more influence on the spatial orientation understanding of students.

Figure 1: Two-dimensional sketch for Introductory CAD course.

Figure 2: Three-dimensional model for Introductory CAD course.

Figure 3: Three-dimensional model after four weeks of the course.

Figure 4: Individual 3D printing project.

Figure 5: Group project with CNC product and final assembly.

Figure 6: Group project with CNC product manufacturing.

Table 1: Descriptive statistics for 3D printing.

Table 2: Paired Sample t-Test for 3D printing.

Table 3: Descriptive statistics for CNC manufacturing.

Table 4: Paired sample t-Test for CNC manufacturing.

Chat with us on WhatsApp