Citation: Iqbal Khan MK, et al. Impact of Various Pre-Treatments on Acrylamide Formation Infrench Fries. Food Sci Nutr Technol 2017, 2(2): 000124.

*Corresponding author: : Muhammad Kashif Iqbal Khan, Department of Food Engineering, University of Agriculture, Faisalabad-Pakistan, Tel: +92(0)3336112737; Email: kashif.khan@uaf.edu.pk

Acrylamide, a carcinogenic compound, is produced in fried and baked food products due to Maillard reaction. In the present study, acrylamide contents were quantified in French fries collected from various fast food chains and local vendors in Lahore& Faisalabad cities. The results indicated that higher acrylamide concentration (higher than permissible daily intake) was found in local vendor & homemade foods. This difference in acrylamide formation is linked with processing time and oil quality. Furthermore, various pre-treatments like par frying, freezing and their combination were studied to reduce the acrylamide in the processed food. Both treatments significantly reduced acrylamide formation (90%) in fried foods at lab scale. Moreover, these pre-treatments have significantly reduced acrylamide (40%) in local vendor process food without changing the frying conditions and oil quality.

Keywords: Acrylamide; Toxicity; French fries; Parfrying; Freezing

Acrylamide (2-propenamide, C3H5NO) is a low molecular weight hydrophilic compound used for the preparation of polyacrylamide; a compound used in plastics as an electrophoresis medium. It is a toxic aliphatic amide (a colorless and odorless crystal) with a relatively high melting point i.e. 84.5°C [1,2]. Chemical structure of acrylamide enables it to dissolve and penetrate in both polar (blood) and non-polar (plasma membrane) media. The ability of acrylamide to bind with hemoglobin, DNA, and other cellular proteins makes it potential carcinogen for humans. It has been reported to cause endometrial, kidney and ovarian cancers [2-5]. Estimated average intake of acrylamide from foods is 0.4- 3.4 µg/Kg body weight per day [6-8].

Acrylamide is produced in carbohydrate-rich foods (potato and cereal based products) that are subjected to high temperature processing. Its formation in foods is linked with Maillard reaction; involving asparagine amino acid and carbonyl group of sugars [9]. Detection of acrylamide in foods has been an intensive area of research since its discovery in processed foods. Fried and baked goods (French fries, bread, biscuits, etc.) represent a class of foods in which the ingredients and processing conditions can promote the acrylamide formation. Some investigations on fried and baked foods consisting of meat and flour have reported the acrylamide concentrations up to 100µg/Kg [6,10]. Acrylamide concentration in fried and oven baked potatoes, breads, biscuits, crackers and breakfast cereals has been reported to be in the range of 100-1000 µg/Kg [11-13].

Deep frying and baking are common practices in Pakistan for various food products. Repeated use of oil and longer frying time (to get specific color and taste) are common practices in vendor foods and foods prepared in fast food chains. Both of these factors facilitate the formation of acryl amide in finished products. Therefore, level of acrylamide in such foods is expected to be a serious concern and needs to be investigated. In current study, French fries procured from local market were investigated for their acrylamide contents as representatives of fried food products. Moreover, potential of various pre-treatments in reducing acrylamide contents during processing have been studied.

Procurement and preparation of French friesCommercially available French fries were purchased from famous multinational fast food chains (FFC) and local venders (LV). Moreover, French fries were prepared in laboratory as an analogue to fries usually made at home without coating of the slices (homemade, HM) for comparative studies and to optimize the processing conditions for minimal formation of acrylamide.

Pretreatment of French friesTo investigate the effect of pre-treatment on acrylamide formation, French fries were pretreated with different techniques including blanching/par frying, freezing and combination of both (par frying and freezing).A control sample (without any pre-treatment) was also prepared for comparison purposes. These pretreated samples were fried in laboratory and local vendor place to investigate the influence of oil quality on acrylamide contents.

Par frying/blanching: Potatoes were washed to remove the dirt and other impurities followed by slicing. The sliced potatoes were then blanched in hot water (70°C) for 15 min. After blanching, potato slices were dried at room temperature. Freezing: Potato slices were stored overnight at -6°C in refrigerator. Frozen slices were thawed prior to frying in heated oil.

Par-frying and freezing: Sliced potatoes were first blanched at 70°C for 15 min followed by overnight storage at -6°C. All the pre-treated samples were fried in pre-heated oil at 140°C for 4 min in laboratory. The samples of same pre-treated potatoes were also processed by the local vendor and were subjected to acrylamide determination.

Determination of acrylamideAcrylamide contents in all samples were determined with HPLC (Shimadzu, Japan). The sample preparation and acrylamide determination was carried according to method developed by Khoshnam, et al. (2010) [14] with some modifications. The samples were ground, homogenized, defatted and were dried under vacuum conditions. Acetone and deionized water were added in defatted samples and sonicated in ultrasonic bath cleaner for 20 min at 40oC.Afterward, samples were centrifuged(Hettich Zentrifugen, Germany) at 2000 rpm for 10 min. Supernatant layer was separated and dried with nitrogen evaporator (Parker, USA).

For HPLC analysis, dried samples were mixed with deionized water and filtered with0.20 µm syringe or micro filter. Filtrate was placed in HPLC vial and injected to column (C-18 reverse phase; 250×4.6mm). Flow rate and temperature were set at 0.20ml/min and 30oC, respectively.

Quantification of Acrylamide: Various concentrations of acrylamide standard were prepared from a stock solution. The stock solution of acrylamide was prepared by dissolving 10mg acrylamide in 10mL deionized water in a closed volumetric flask. Then successive dilutions of acrylamide (0.1, 0.2, 0.3, 0.4 and 0.5 µg/mL) were prepared with deionized water and stored at 4oC for further use. These solutions were analyzed with HPLC for standardization. The acrylamide content in the samples are reported as µg/g.

Statistical Analysis: All experiments were performed in triplicates and results were reported in terms of means and standard deviations.

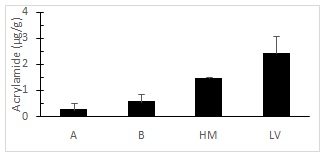

Results and DiscussionAcrylamide contents in various French fries samples obtained from different sources are shown in (Figure 1). Acrylamide contents in all collected and prepared samples were found to be higher than permissible limit (0.002- 0.004 µg/kg) [15]. French fries from local vender (LV) contained highest level of acrylamide (2.429 µg/g) followed by homemade (HM) fries (1.46 µg/g). The lack of controlled processing conditions and repeated frying in the same oil are common practices observed by the local vendors. These factors are mainly responsible for high acrylamide contents and large standard deviations in French fries prepared by local vendor. It has been reported that excessive frying of oil converts the fatty acids into acrylic acid and acrolein which facilitate the synthesis of acryl amide [16]. Samples from FFC (A and B) contained 0.559µg/g and 0.255µg/g, respectively. All these concentrations are higher than permissible limits and expected to cause health issues if consumed in excessive amounts. The acryl amide contents in homemade samples were in between the FFC and LV samples. The higher values compared to FFC samples are may be due to absence of any pre-treatment and coating in case of HM samples and difference in processing conditions. On the other hand, lower value compared to LV samples are may be due to fresh frying (i.e., no repeated frying).

In the present study, there were a number of factors that were uncontrollable, i.e., usually it is very hard to get information about potato varieties, pretreatment of slices, coating of slices, processing conditions, etc. from any food processing industry, fast food chains and local vendors. All of these uncontrollable factors actually resulted in large deviations from the mean acrylamide contents for most of the samples. As an example, the effect of processing conditions has been discussed in the next section. Here, it is important to mention that in spite of these uncontrollable factors, there was a clear trend among all the samples that is useful to know for the consumers of these products.

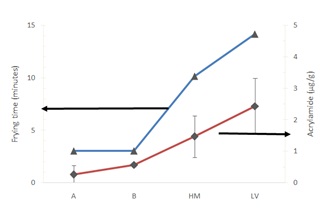

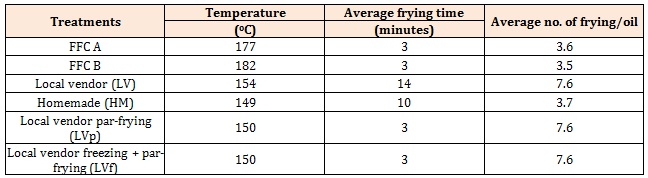

Effect of Processing Conditions on Acrylamide ContentsIn the present study the results were also compared in terms of varying processing conditions, such as time, temperature and number of fryings. The results showed that the time and temperature combination has a significant impact of acrylamide formation. The difference between acrylamide contents between A and B samples were due to different frying temperature for the same frying time, i.e., 177 oC for 3 min and 182 oC for 3 min, respectively. Earlier, it was reported that a small change in temperature (5 °C) doubles the acrylamide content in processed foods [17,18]. The acrylamide contents as a function of time and temperature for the all the samples are presented in (Figure 2). It has been reported that an increase in temperature above 120oC initiates Maillard reaction and acryl amide formation [17]. As frying temperature for all the samples were above 120 oC, the frying time has a significant effect on acrylamide formation as indicated by higher values for samples HM and LV compared to samples A and B.

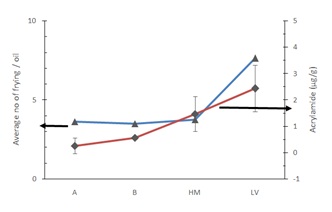

Besides processing time and temperature, number of frying per oil also influenced the formation of acrylamide. In local vendor, number of frying exceeds to seven time and resulted in highest acrylamide contents (Table 1). Similarly, lowest acrylamide contents in commercial brands were due to one frying compared to three fryings in FFCsamples (Figure 3). Excessive frying per oil does not only reduce the quality of oil but also facilitates the formation of acrylamide. In these conditions, acrylamide formation occurs due to Maillard reaction as well as due to acrolein and acrylic acid synthesis pathway. In this pathway the fatty acids are converted into acrylic acid and acrolein, which are then converted into acryl amide [16]. This could be possible reasons for higher acrylamide contents, especially in local vendor foods.

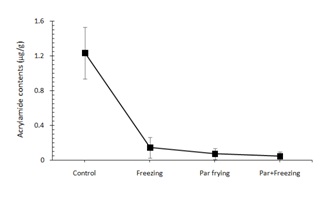

Effect of Pre-Treatments on Acrylamide FormationAlthough acrylamide formation can be minimized by reducing the number of fryings, but this may not be feasible from economic point of view, especially for the local vendors. Alternatively, different strategies may be adopted to minimize the acrylamide formation. For the purpose, different pre-treatments (i.e., par-frying, freezing and their combination) of the potato slices were evaluated and compared with control (untreated) sample for acrylamide contents. As shown in (Figure 4), the pretreatment of the potato slices significantly reduced the acrylamide formation. The combined treatment (parfrying and freezing) reduce the acrylamide contents formation upto 96% followed by par-frying (92%) and freezing (80%).Thus, these pre-treatment emerges as a new tool to reduce acrylamide in French fries.

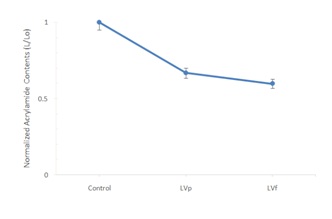

The reduction in acrylamide contents due to these pretreatments may be attributed to leaching of sugars (in par-frying) and inactivation of enzymes (by par-frying and freezing). It has been reported that soaking reduces the concentration of precursors (reducing sugars) required for Maillard reaction [19-21]; thereby, reducing the acrylamide content in end product. Moreover, pretreated samples were fried in the oil collected from local vendors and were compared with untreated French fries sample (control). The results indicated that oil quality did not influence on the acrylamide formation. The oil was used in number of frying and acrylamide contents are still lower than permissible level. It indicates that pretreatments of French fries significantly reduced the acrylamide formation. Lowest acryl amide formation was found in mixed treatment (40% reduction) followed by Par frying (34% reduction).

The results of the present investigation have demonstrated that through careful optimization of the processing conditions and through proper selection of pre-treatment of potato slices, the acrylamide formation can be significantly reduced in potato fries. The results presented here are quite pragmatic for consumer as well as for food processor owing to related health and economic implications.

ConclusionAcrylamide formation in French fries varied with processing conditions. Highest acrylamide amount was found in samples of local vendor due to temperature and more number of frying per oil than recommended. However, acrylamide concentration was significantly lowered in FFC samples that process French fries at recommended temperature and other processing condition. Moreover, pre-treatments of the potato slices like par-frying and freezing significantly reduced the acrylamide contents in French fries (90%). Thus, parfrying and freezing can be applied to reduce acrylamide along with proper optimization of the processing conditions.

Figure 1: Acrylamide contents in various French fries samples analyzed with HPLC (A, B: fast food chain A and B, HM: Homemade, LV: local vender).

Figure 2: Influence of frying time on acrylamide formation in various types of French fries (A, B; FFCs A and B, HM; homemade; LV; local vender).

Figure 3: Influence of number of frying per oil on acrylamide formation in French fries samples (A, B:FFCs A and B, HM: homemade; LV: local vender)

Figure 4: Influence of various pretreatments on the formation of acrylamide in French fries sample prepared in fresh oil at 140oC and frying time was 5 minutes.

Figure 5A: comparison of normalized acrylamide contents in pre-treated French fries prepared at local vendor fryers (control; No treatment LVp; local vendor parfrying, LVf; local vendor par frying + freezing).

Table 1: A summary of processing conditions of French fries reported in this article.